WHY FINISHLINE?

For Metal Fabricators who are motivated to improve upon operational efficiencies and part consistency, FINISHLINE is an innovative metal finishing machine that is tailor made for your specific needs.

What Our Customers Have to Say

FINISHLINE The leading edge

For Metal Fabricators who are motivated to improve upon operational efficiencies and part consistency, Finishline is an innovative metal finishing machine that is tailor made for your specific needs.

INTELLIGENT DESIGN. UNCOMPROMISED QUALITY

FINISHLINE provides a compact all-in-one solution utilizing intelligent design and quality components for finishing parts originating from laser, plasma, waterjet, or punch processes.

Significant advantages of investing in quality deburring and finishing solutions are efficiency, safety, and repeatability. With FINISHLINE, different finish qualities can be achieved while working with a variety of part profiles. You’ll see how a FINISHLINE machine will dramatically expand your shop’s capabilities.

MEET FINISHLINE

We're continually working to change the way people think about secondary processes. Learn more about the ways in which our innovative machine can help your company grow.

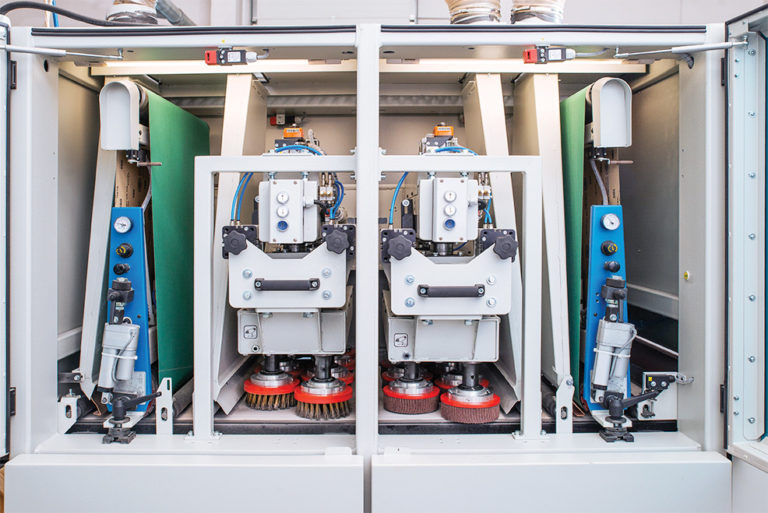

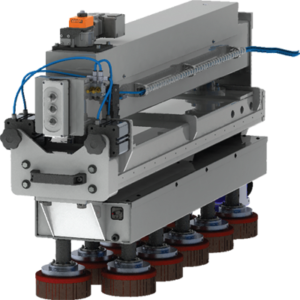

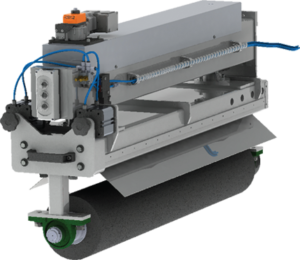

WORKING UNIT

As a solution to your particular needs, FINISHLINE metal finishing machines are available in a variety of widths and with one to six working units. Desired part finishes can be efficiently achieved with the use of a single unit or with a variety of combination. Achieve the results you want with the control you deserve.

Schneider Electrics

Proven quality systems

ROLLON SLIDING SYSTEM

Performance within reach

SWIVEL CONTROL PANEL

Control where you need it

Perfection Made Possible

Whether you are looking to process parts from your laser, waterjet, or punching applications FINISHLINE has the ability to make your parts perfect. Browse just some of the parts that have come off the FINISHLINE machine and contact us today to learn how we can help you and your business get the finish you’ve always wanted.

Request Sample Parts

Interested in having your parts run? Contact us today and see for yourself how FINISHLINE can help your company succeed.

PROCESS OF PRECISION

Flexibility, precision, and productivity inspired the design of the FINISHLINE metal finishing machines by Mid Atlantic Global. Deburring, edge rounding, oxide removal, slag removal, graining, and polishing with one compact design and with one economic investment. Achieve increased operational efficiencies and superior quality with FINISHLINE.

Deburring and Graining

Optimal Finish Quality

Variable speed control: 1,400 - 3,550 sfpm Roller hardness: 35 - 70 shore Roller diameter: 5", 7", 9"

Edge round, Oxide & Slag removal

Versatile Application

Variable speed control: 460 - 1,500 rpm

Quick change brush system

Full surface contact

Surface Polishing

Refined Results

Variable speed control: 460 - 1,500 rpm

Available brush diameter: 8", 12"

MACHINE SPECIFICATIONS

The FINISHLINE machine is an all-in-one solution due to the variety of both standard and optional features. Read below to learn more about the different series and to see which machine could be the one for your particular application.

5 SERIES

Model 2550

7 SERIES

Model 4300 | Model 5100

9 SERIEs

Model 4300 | Model 5100 | Model 6300

Machine Series

Series 5 | Series 7 | Series 9

Model 2550 | Model 4300 | Model 5100 | Model 4300 | Model 5100 | Model 6300